Intelligent data management with Industrial Identification

Small batch sizes, the need to manufacture products of ever increasing complexity in many different versions, an extremely

high level of customization, and demanding processes with direct supplier involvement are creating major challenges for industry.

Siemens’ response to these challenges is SIMATIC Ident, a uniquely comprehensive and scalable portfolio of radiofrequency identification (RFID) and optical identification systems for the flexible, efficient, and economical implementation of identification solutions in manufacturing and logistics.

SIMATIC Ident also supplies production data to cloud platforms such as MindSphere, the cloud-based, open IoT operating system from Siemens, making it one of the key technologies on the path to digitalization.

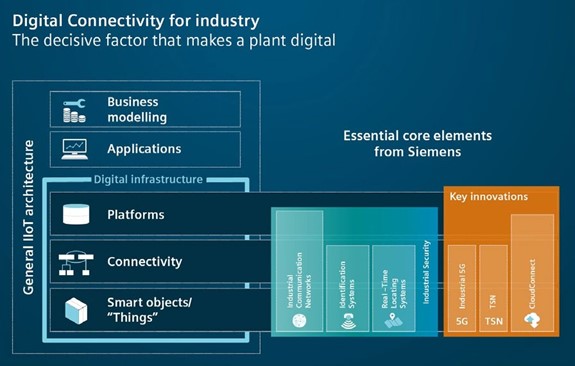

Digital Infrastructure for Industry

The digital infrastructure is the key variable for anyone who wants to fully exploit the opportunities of digitalization. Almost invisibly, it provides the necessary connections between all objects, systems, and applications, transforming a plant into a smart plant, things into the Industrial Internet of Things, and ideas into reality. As an essential core element of the digital infrastructure, SIMATIC Ident offers an efficient and economical solution. Along with locating systems, network solutions, industrial security, and future key technologies, you benefit from a powerful foundation for all present and future IoT applications.

Digitalization also means: making suppliers part of the network

Suppliers become real partners when you make them a part of your network. Everyone benefits when suppliers and manufacturers form part of a greater whole. Everything becomes more closely interlinked, and everyone can respond more quickly to changed requirements. Industrial Identification, a centerpiece of the digitalization of the future, always remains in the background. Everything is built on a foundation of software and hardware solutions that can be used to seamlessly integrate and digitalize the entire value chain, including all suppliers.

Productivity Demands Precision

Industrial processes in the digital enterprise demand total transparency. The ability to gather and process data at strategically relevant points is more and more becoming a determining factor in achieving long-term business success. As a result, Industrial Identification is developing into a key technology for the Digital Enterprise. Our solutions close the gap between the real and the digital worlds – and create new potentials for our customers to add value.

Industrial Identification Ensures the Necessary Transparency

What products or components are available, when, where, and in what condition? This overview can be obtained using an innovative identification system. SIMATIC Ident synchronizes the virtual data flows from IT systems with the actual flows of goods along the entire value chain. In an industrial environment in particular, data transparency is increasingly becoming a key success factor.

Processes are Becoming Smarter and More Flexible, Economical, and Efficient

Quality requirements can be met reliably, production can be much more flexible, manual work steps are reduced, and potential sources of error are detected immediately and remedied. This means: more efficiency in logistics, materials management, production, and service.

Comprehensive and Consistent Scalability – Solutions from Siemens

Siemens’ response to these needs is SIMATIC Ident, a uniquely comprehensive and scalable portfolio of RFID and optical identification systems for the flexible implementation of identification solutions. The result: assured competitiveness and a flexible future.

Convincing Advantages

- Complete, scalable portfolio of powerful RFID and optical readers

- Lower engineering costs: simple integration into the SIMATIC automation environment, for example, the TIA Portal

- High process security and fewer downtimes

- Very secure investment thanks to flexible and economical solutions

- Highest reliability as a result of components with a high protection class for use in tough industrial environments

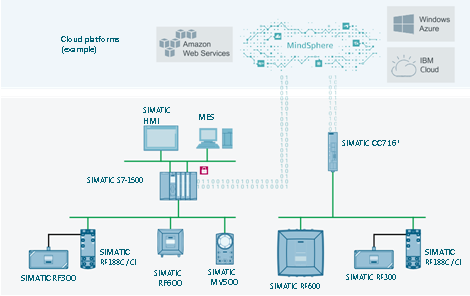

SIMATIC Ident Supplies Production Data to the Cloud

Staying up to date with the entire production and supply chain means having to deal with huge volumes of data. This data comes together at a virtual level– in the cloud – to form the Internet of Things (IoT). But only the evaluation and the use of this data open up unimagined potentials.

SIMATIC Ident – The Easy Way Towards the Digital Future

Siemens has developed a solution with which these potentials can be comprehensively used. MindSphere, the open IoT operating system, supports the digital transformation of companies of all sizes and in all industries in the shortest possible time. The SIMATIC Ident portfolio not only supports the connection to MindSphere, it also enables the use of data in a wide variety of cloud applications. All our Ident systems pave the way for a secure cloud connection via a variety of Industrial IoT gateways, such as SIMATIC CC716* or SIMATIC S71500 with CP1545-1. And this opens up entirely new ways to use data.

More Data for Greater Transparency

Analyzing the data transmitted to cloud applications by SIMATIC Ident makes the production and logistics process transparent, regardless of the manufacturer. This transparency allows production processes and supply chains to be optimized with the goal of improving efficiency and quality in production, logistics, asset management, and other areas in every industry.

A Cloud with Vision

SIMATIC Ident is a key element in a successful digitalization strategy. Together with MindSphere, it lays the foundation for data- based services from Siemens. Via cloud platforms such as MindSphere, this data potential can be tapped across the board. Predictive maintenance uses measured values and data detected by sensors for this purpose, facilitating proactive maintenance of plants and machinery and thus minimizing downtimes. The ability to use the data globally throughout the company helps to optimize supply chains, improve internal production capacity utilization, and increase supply quality – all of which ultimately benefits the customer.

Added Value with Our Systems

Increasing the number of product versions makes both production and the supply chain more complex. It’s therefore important to choose procedures that make both complexity and costs manageable. Tools and processes are the key to efficiently structuring the various tasks involved.

Do you want to be able to control your production flexibly, manage your assets efficiently, track products and components reliably, and synchronize your supply chain intelligently?

Our SIMATIC Ident products and solutions offer the best possible support.

- Manufacture Efficiently- Optimize your production and material flow control

- Assure Quality- Improve customer satisfaction

- Create Transparency- Plan ahead

Manufacture Efficiently – Optimize your Production and Material Flow Control

Machine-readable, automated, and contactless identification systems create improvements all along production and supply chains: manual work steps can be reduced, potential sources of error identified and avoided, and plant availability increased. Production can be structured more flexibly and can be made faster, even with a high level of customization. For example, the sequentially correct delivery of work pieces permits flexible planning of autonomous production steps, which prevents installation faults and the need to rework faults. You benefit from greater efficiency and economy in logistics, material management, production, and service in a wealth of variations.

Assure Quality – Improve Customer Satisfaction

With SIMATIC Ident, every product leaves a digital trace that can be documented at every step, from the creation of the individual components to recycling. This means that fluctuations in product quality can be tracked and sources of error identified and rectified at an early stage. In logistics, the systems make it possible to identify, analyze, and rectify weak points in the process. Legal requirements – for example, in the pharmaceutical or food industries – can be reliably satisfied using Industrial Identification.

Create Transparency – Plan Ahead

What products or components are available, when, where, and in what condition? SIMATIC Ident provides fast and reliable answers to these questions. With RFID and optical reader systems from Siemens, all products and parts can be monitored in real time at all stages of the transport process, and external sequences can be better integrated into actual production.

And as the digital transformation progresses, we can achieve even more: virtual data flows and real product flows will come together to produce maximum transparency in both production and logistics processes. This makes it possible to not only analyze and visualize the track-and-trace information but also to ensure that the analyzed data is available worldwide. So that products arrive more quickly where they need to be: with customers.

Compact, robust, for every scenario

Industrial Identification systems allow to meet the constantly growing requirements in production and logistics. They are convincing thanks to their high level of data security, and they meet the growing demand for end-to-end traceability of products and processes.

RFID

Our RFID systems SIMATIC RF cover all kinds of requirements in terms of performance, range, and frequency range. You can be confident of complete transparency along the entire supply chain, so there’s no need for a line-of-sight connection between the read / write device and the transponder.

Robust and compact readers class with a high degree of protection, with the option

of an integrated or external antenna, are available to provide you with fail-safe data communications. Cost-efficient, maintenance-free, passive labels and passive transponders in a variety of designs and storage capacities are readily available, along with powerful antennas.

Optical Identification

The SIMATIC MV optical readers are powerful, intelligent readers for both simple, high-contrast 1D / 2D codes and for hard- to-read DPM codes marked on different product surfaces. The optical readers also provide the option of text and object re- cognition and verification of the quality of marking. The readers in the SIMATIC MV family also score high thanks to their high- quality image capture at different resolutions and integrated lighting. The readers can thus be used in a variety of ways in production and logistics. Ease of handling is ensured by the ability to configure the device using Web Based Management and system integration via the TIA Portal.

Why choose Siemens? What’s special about us?

Siemens AG is the only company anywhere in the world that already has a fully integrated portfolio covering all aspects of digitalization. We’ve acquired more than 30 years of experience in the fields of RFID and optical identification, and we’ve always been a driver of innovation. Hundreds of businesses around the world benefit from our technology. But that’s not all:

Maximum Flexibility for Our Customer’s Requirements

We’re one of the few providers with an integrated portfolio – from the field level to the cloud: RFID systems for production and logistics, locating systems and optical readers. We provide objective, technology-neutral consulting, which makes us both a professional and a reliable partner. Ident customers get the best possible solutions from us.

Unique Skills for Comprehensive Solutions

Customers benefit from our many years of experience in technology and our comprehensive automation and integration expertise. We, in cooperation with Siemens worldwide, can also offer wide-ranging professional solutions and industry know-how.

Our Future Security is Your Future Security

Our customers’ investments are futureproof, because subsequent technology upgrades can be implemented in the automation landscape easily and flexibly: for example, using standardized functional modules with no need for costly changes (migration strategies). Likewise, when expansions are required, the existing identification solution can be developed using technology-neutral principles. Complete identification solutions can be implemented and expanded in this manner.

Integration in TIA and the IT Environment

This, too, is unique worldwide: the integration of SIMATIC into the TIA environment. This effectively turns the product range into the solution. Integration into the IT environment is another solution that only a few suppliers can offer. Our integrated reader technology can be used in both PLC and IT environments, so our products become the link between real and digital processes – in every sector.

Benefits at a Glance

- Integrated product range for Industrial Identification, location, communication, and security – unique around the world.

- A harmonious portfolio landscape makes everything easier: for example, programming, maintenance, commissioning, and diagnostics.

- Vertical integration: integrated reader technology.

- Horizontal integration: from production to logistics, in other words, the entire value chain.

- Expertise in digitalization and Industry 4.0.

- Support for a range of protocols including PN, EIP, OPC UA.

- Connection to cloud applications such as MindSphere, the cloud-based, open IoT operating system from Siemens.

![SIMATIC WinCC Unified Software Visual [RGB] SIMATIC WinCC Unified Software Visual [RGB]](https://appliedc.com/wp-content/uploads/elementor/thumbs/Siemens-WinCC-Unified-Software-Visual_small-qmrgrir4mxp70000e85ol9rpzjlmet1zif3yfklxvc.jpeg)